Research|Chiba Laboratory|Deformation Processing, Institute for Materials Research, Tohoku University

Research

Aims and scope

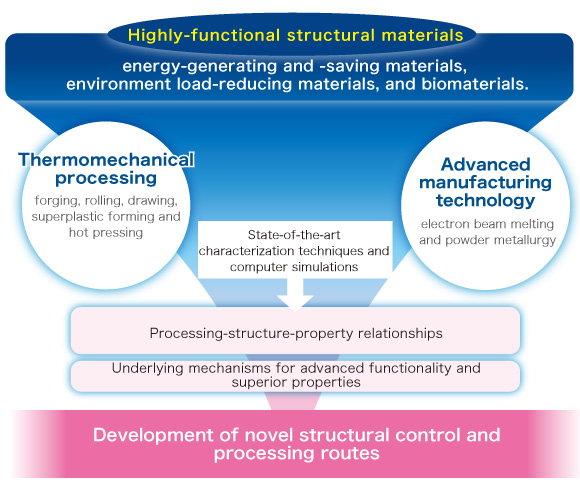

In order to maintain the sustainable development of the society for human being, it is of crucial importance to develop the new types of highly-functional structural materials such as energy-generating and -saving materials, environment load-reducing materials, and biomaterials. In our laboratory, we are aiming at systematizing the processing-structure-property relationships in structural metallic materials through the systematic examination and analyses for macro-, micro- and nano-structures evolved during the plastic deformation concomitant with heat-treatment, i.e., cold- and hot-forging, rolling, extrusion, swaging, wire-drawing, and hot-pressing. In addition, we are studying on advanced processing technology including additive manufacturing using electron beam melting (EBM), spark plasma sintering (SPS) and plasma rotating electrode process (PREP). By employing the state-of-the-art techniques for characterization and computer simulations, fundamental studies are carried out to reveal mechanisms of occurrence of some specific properties for such advanced materials and to establish the processing and the synthesis for producing the most favorable microstructures to realize the best performance of the materials.

Research Topics

We study the processing-structure-property relationships in structural metallic materials, with particular emphasis on biomedical Co–Cr alloys, Co-/Ni-based superalloys and titanium alloys, aiming to develop novel design and manufacturing process for superior properties. In addition, researches on advanced technology such as additive manufacturing based on electron beam melting (EBM), computer simulations and intelligent (smart) forging techniques are explored.

- Phase transformation and high temperature deformation behavior in biomedical Co–Cr alloys

- High temperature strength and plastic deformation of Ni- and Co-based superalloys

- Tribocorrosion behavior of Co–Cr-based alloys

- Microstructural control and deformation processing of structural titanium alloys

- Development of novel high functional metallic alloys (Mg, Cu, W, magnetic materials etc.)

- Intelligent (smart) hot working technique of metallic materials

- Additive manufacturing using electron beam melting (EBM)

- Computer simulations of microstructural evolution and plastic deformation

Achievements

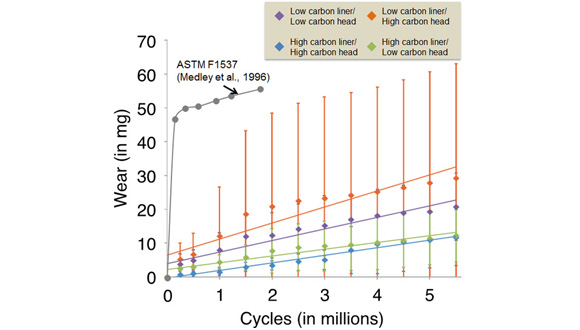

Wear behavior of COBARION® metal–on-metal hip joint bearings

Co–Cr–Mo alloys with excellent wear resistance have been used in artificial hip joint bearings. In particular, metal-on-metal (MoM) total hip arthroplasty with large Co–Cr–Mo alloy heads prevent early dislocation and have received great attention from the viewpoint of QOL of patients. However, the biological reactions due to the wear debris generated have become a problem in the MoM artificial hip, the improvement of wear resistance of the Co–Cr–Mo alloy is indispensable for realizing long-life artificial hip joints. We evaluated tribological properties of the originally developed Co–Cr–Mo alloy "COBARION" using a hip simulator, in collaboration with Professor Hani Haider, University of Nebraska Medical Center, who is an expert on in-vitro testing of orthopaedic implants. It was shown that the MoM bearings made of the COBARION have the most excellent tribological performance among the existing artificial hip joints.

A wear simulation test was performed at the laboratories of the University of Nebraska Medical Center on COBARION Co–Cr–Mo MoM components.

Average wear of the COBARION MoM components, head and liner wear combined.

| Department of Orthopaedic Surgery and Rehabilitation,

University of Nebraska Medical Center http://www.unmc.edu/orthosurgery/ |

|

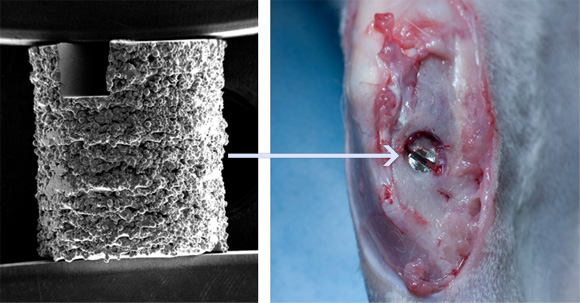

Osseointegration in Co–Cr–Mo alloys

In order to enable prolonged use of the prosthesis, strong bonding between implants and bone is necessary. Therefore, a technique to promote bone formation by coating the porous layer on the implant surface to induce bone cells into a void portion of the porous layer has been developed. However, most of such studies are done exclusively on titanium alloys. We evaluated the binding affinity for bone and Co–Cr–Mo alloys, in collaboration with Professor Peter Thomsen, University of Gothenburg, who leads a field of "osseointegration" regarding the binding of metal implants and bone. From the results of animal experiments, we found for the first time that osseointegration also occurs in Co–Cr–Mo alloys, similarly to the titanium alloy. In addition, it was shown that small amount of additive elements improve the binding significantly.

Animal experiments to investigate osseointegration of Co–Cr–Mo alloys.

| Department of Biomaterials,

Sahlgrenska Academy at University of Gothenburg http://www.biomatcell.org.gu.se/biomatcell/ |

|

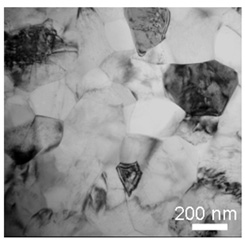

Ti–6Al–4V alloy with an ultrafine-grained microstructure exhibiting low-temperature–high-strain-rate superplasticity

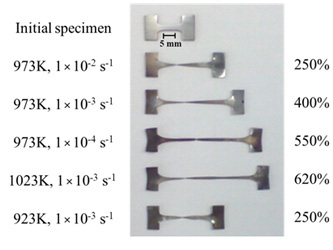

We has proposed a novel processing route of titanium alloys "α' processing", which utilizes α' martensite. In collaboration with the Professors Damien Fabregue and Eric Maire, INSA-Lyon, we developed α' Ti–V–(Al, Sn) alloys with low elastic modulus and high strength. Recently, by using the α' processing, we also succeeded in developing the novel Ti–6Al–4V alloy showing the low temperature–high strain rate superplasticity. The ultrafine-grained Ti–6Al–4V alloy was produced by simple hot working of the α′ martensite microstructure alloy. The alloy exhibits superplasticity even at low temperatures (below 973 K) and high strain rate (10−2 s−1). Superplastic forming has been frequently used for conventional microcrystalline Ti–6Al–4V alloys under high temperatures of more than 1123 K and low strain rates of less than 10−3 s−1, thereby restricting their practical application to specialized areas such as aerospace. Therefore, the α' processing has a great potential for application as cost-affordable next-generation superplastic Ti alloy. A collaborative work on superplasticity of nanocrystalline Ti–6Al–4V alloys is being conducted with Professor Gérard Bernhart, Ecole des Mines d'Albi-Carmaux, France.

|

|

Ti–6Al–4V alloy obtained by "α' processing". The ultrafine-grained metastable α structures (average grain size: 200 nm) showed excellent superplastic properties.

| INSA-Lyon http://www.insa-lyon.fr/en |

|

| Ecole des Mines d'Albi-Carmaux http://www.enstimac.fr/ |

|

Electron Beam Melting

Under construction